Reliability

Maintaining service reliability is a top priority for Con Edison. This aspect of our sustainability is presented in terms of infrastructure investment by each company within Con Edison, the performance of our electric, gas and steam systems, and both the upgrades and lessons learned from key developments realized in 2013.

Electric

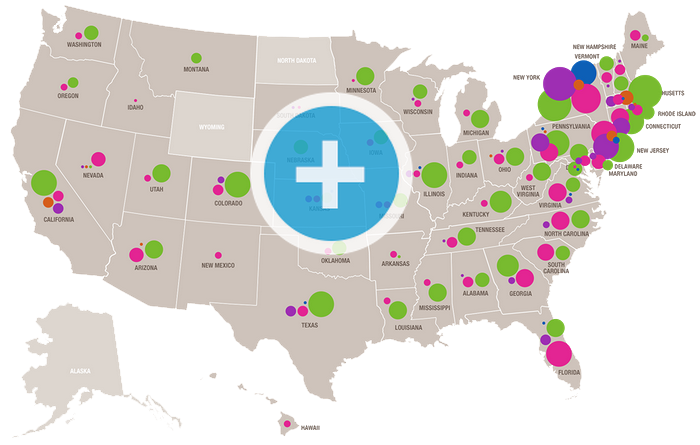

Con Edison is known for being one of the most reliable electric service providers in the U.S.—and has been the recipient of numerous reliability awards over the years, including PA Consulting’s 2013 ReliabilityOne award for the Northeast region. In 2013, the reliability of Con Edison of New York’s overhead power distribution system was 85 percent better than the industry average. When our underground system is included, the system is nine times more reliable than the national average. In 2013, Orange and Rockland set a company record for reliability performance, reflecting fewer non-storm-related service interruptions than ever before.

Peak Performance

Con Edison of New York’s e system performed very well in 2013, successfully serving a record peak demand of 13,322 MW on Friday July 19th, marking a recovery to pre-recession demand levels. Overall demand for electric energy exceeded 56,918,000 MWh in 2013, reflecting stronger weather patterns and growing economic activity. Demand for electricity grew fastest in Manhattan last year, at three percent year-over-year growth, compared to a range of 0.4 percent to 1.8 percent growth in the other boroughs and Westchester. Distribution feeder lines marked their best performance in 10 years and the system experienced fewer transformer failures than in any of the past five years, despite July weather that made the month the eighth warmest on record for the region.

Orange and Rockland successfully met a peak demand of 1,561 MW on July 18, 2013. Overall demand for electric energy on the Orange & Rockland system exceeded 5,721,000 MWh in 2013. The system performed remarkably well throughout the remainder of the year, cutting the frequency of non-storm-related service interruptions to the lowest level on record.

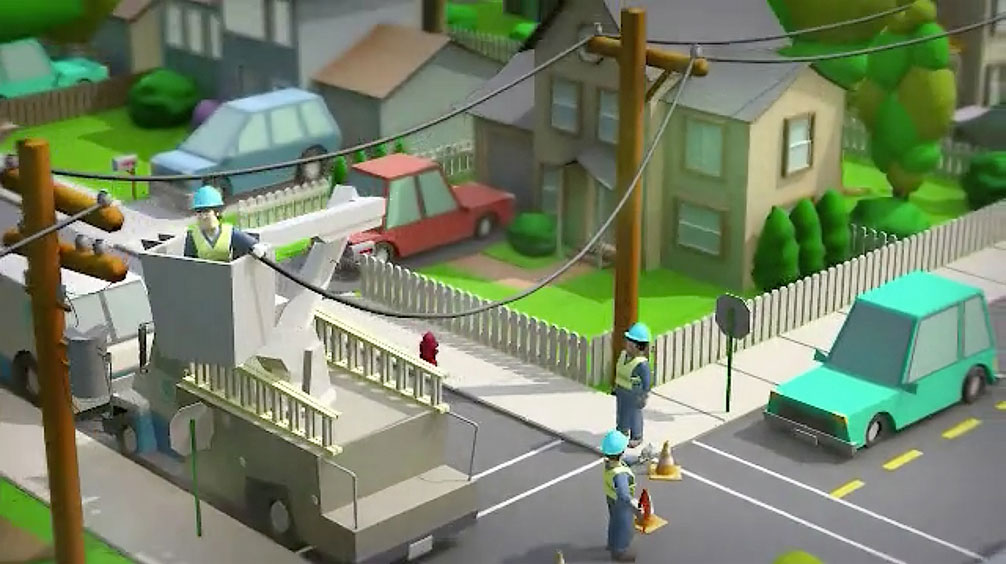

Con Edison of New York and Orange and Rockland completed key electric infrastructure improvement initiatives in 2013, fortifying lines and equipment across the service territory. As in years past, we employed innovative techniques to meet increased demand in growing communities. Through reconfiguring existing system components, we boosted capacity of distribution networks in the Fordham Heights section of the Bronx and in lower Manhattan, avoiding costly transformer upgrades and the installation of additional cable. The completion of a smart distribution automated loop system in the Park Slope section of Brooklyn also enabled greater operational flexibility, providing needed load relief during periods of high demand. Another network reconfiguration completed in 2013 is using new technology to enhance reliability for 120,000 customers in Flushing, Queens.

Smart Grid

In addition to strengthening our system to better serve growing communities, we’re making our electricity networks smarter through leading-edge smart grid distribution automation technologies. In 2013, we installed more than 4,000 smart devices across our system, including remote sensors, monitoring systems, synchrophasors, and switches. Each device is integrated into our enhanced control system, expanding operators’ real-time view of system conditions and increasing their control over the system.

We also partnered with our customers to successfully demonstrate a distributed energy resource management platform that seamlessly integrates customer-sited resources into a grid operator’s toolkit. The pilot demonstration included distributed generation, building management systems, battery storage, photovoltaics, and electric vehicles.

Energy Highway

In addition to strengthening our distribution networks, we are also partnering with other utilities to bolster New York’s high-voltage transmission system. For more information on this topic, please read on within the Policy Management and Regulatory Impact section of this report

Key Event: Metro North

On September 13, 2013, Con Edison helped Metro North prepare for upgrades to their system by removing a key power delivery line from service. With the line out of service, Metro North and Con Edison planned to work on key system components and reconnect the line once upgrades were complete. The temporary system configuration left a key section of Metro North’s system powered by a single power-delivery connection to Con Edison’s system.

As work was nearing completion twelve days later, the single line serving the Metro North system was damaged during our ongoing work to upgrade the facility. The damaged line could no longer provide service to Metro North’s system, leaving a portion of the New Haven line without electricity and disrupting train service for roughly 50,000 Metro North riders on September 25th, 26th, and 27th.

Con Edison worked hand-in-hand with Metro North to safely restore service as quickly as possible. When Metro North’s original contingency plan to connect to Connecticut’s power supply system failed, Con Edison designed an alternative. Within eight hours, we had begun physically re-configuring our local residential distribution system nearby to support the large amount of power Metro North required. Working together, Metro North and Con Edison successfully restored partial service to the affected train route by Monday the 28th and had restored full service by the following Monday.

As a result of the event, we have reviewed and enhanced work practices to mitigate the potential for a similar delivery line failure. Metro North has also upgraded its contingency plan resources.

Gas

Safely and reliably supplying natural gas service to our more than 1.2 million gas customers is a daily focus for both Con Edison of New York and Orange and Rockland. The fuel provides many benefits, including lower emissions and more moderate prices than heating oil alternatives. To meet rising customer demand, we are enhancing our infrastructure to increase capacity and to protect our customers from any reliability impact that might arise from a disruption to the interstate pipeline system.

For all its benefits, natural gas also has risks. The invisible fuel dissolves in air and can only be detected by an odorant that is added to the fuel for safety or by specialized instrumentation. To protect customers, Con Edison of New York and Orange and Rockland work steadily to quickly respond to leak reports, identify, repair, and replace leak-prone pipes, and survey the system for new damage following weather events.

System Performance

Con Edison of New York customer use of natural gas reached its highest level in 2013 on December 17, when 1,596,947 Dth were drawn through the system. Con Edison of New York's total sales and transportation of natural gas reached nearly 280 billion Dth by year end, 2 percent higher than in 2012. Leak response improved in 2013: our personnel were on location within 30 minutes for 89.0 percent of the total possible leaks reported, and within 45 minutes for 99.4 percent of possible leaks reported.

In Orange and Rockland, customer demand peaked at 202 million Dth on January 7. Throughout the year, Orange and Rockland sales and transportation of natural gas reached over 28 billion Dth of natural gas, 17 percent more than in 2012

Infrastructure Upgrades

Key improvements were made to our natural gas transmission and distribution network in 2013 to meet growing demand and enhance system reliability. Con Edison’s main replacement program continued, replacing 52 miles of leak-prone iron and steel pipe. We have replaced 279 miles of leak-prone pipe over the past five years.

Significant upgrades were also made to Con Edison’s natural gas transmission interconnection infrastructure to increase capacity. A new interconnection to Con Edison of NY’s service territory was brought into lower Manhattan via the Texas Eastern Transmission (TETCO) pipeline. The project increases pipeline capacity into the Con Edison system and significantly improves system reliability in the event of an unexpected disruption at other transmission interconnections. Additional upgrades were made to pipeline system components serving the territory to increase capacity.

Orange and Rockland also continued to replace cast iron and steel mains in 2013. In 2013, they replaced 93,000 feet of main, surpassing their goal of installing at least 90,000 feet annually. It has replaced 83 miles of leak-prone pipe over the past four years, significantly enhancing customer safety in the region.

Both utilities survey their entire natural gas distribution infrastructure annually to detect outdoor leaks that may be emanating from underground pipes. We also conduct spot checks following major weather events to ensure storm water, salt, or road damage has not impacted our infrastructure. Both utilities also conduct annual customer awareness campaigns, sending scratch-and-sniff mailings to every customer to remind them what gas smells like and to encourage them to call as soon as they suspect a leak.

Key Event: Nyack College

On June 4, 2013, a grounds worker at Nyack College was leveling out some terrain on a hillside behind the college gymnasium. While digging with a backhoe, he struck and pulled a buried steel pipe with the bucket of the machine—setting in motion a chain of events that would injure eight people and destroy part of the historic campus.

The worker had struck a natural gas service line and pulled it from a coupling located several hundred feet away. Though he couldn’t smell gas—and noticed no damage to the pipe where he stood—a one-inch gap had opened up at the coupling. Natural gas began to leak through the gap and migrated into the sewer system beneath the college. Since he saw no damage, the worker decided not to report the incident. Within a few hours, significant amounts of natural gas had accumulated in the basements of several buildings via the sewer system. All it took was something as small as a spark from the flip of a light switch to cause an explosion in the campus’ historic Sky Island lodge.

Orange and Rockland responded to the event and took immediate action to reduce the risk of further injury to people or damage to the campus. With the help of the local fire and police departments, they evacuated students and faculty in the surrounding buildings, cut power to the campus, and discovered the source of the leak.

The event underscores the danger natural gas can pose when leaks or damage to underground infrastructure go unreported. Con Edison of New York and Orange and Rockland are members of Dig Safely New York, which provides a toll-free “Call Before You Dig” service for contractors and homeowners. Dial 8-1-1 to schedule a mark out before you dig.

Steam

Con Edison provides steam service to customers in Manhattan, represented by about 1,700 accounts, through an underground network of steam pipes. By generating steam in large quantities at our generating stations, we increase the efficiency of steam production and reduce emissions that would otherwise be generated by customer-sited boilers and equipment. Con Edison’s steam system is changing to reduce costs to customers and to improve our environmental footprint.

Our steam system performed well in 2013, meeting a 2013 peak demand of 8.9 million pounds per hour on January 23. The system experienced no major service disruptions, maintaining its 100 percent reliability rate. Our focus on public safety continued in 2013, as we developed and integrated remote monitoring of structures prone to impact following major weather events.

Gas Addition

Two Con Edison steam generating stations were converted in 2013 to burn natural gas as a primary fuel instead of oil, reducing fuel costs and emissions. The changes will cut CO2 emissions from the two stations by 23 percent (148,000 tons) each year and reduce customer costs by about 8.5 percent. In 2013, 90.9% of our steam was generated by burning natural gas. The units remain capable of burning either fuel in a supply shortage, increasing Con Edison’s steam fleet’s dual-fuel capability to roughly 88 percent of generation from 62 percent. This capability is particularly important to maintaining reliability and moderating price impacts during periods of high demand for natural gas, such as those we recently experienced.

Infrastructure upgrade

In addition to the steam generation upgrades discussed above, key enhancements were made to the steam distribution system in 2013. They included expanding the range of pressure used in the system. We consulted extensively with customers who would be affected by the change and ensured a smooth transition as the change was made. The new operating pressure will allow more efficient steam generation units to meet demand more of the time, reducing cost and emissions.